[ By Delana in Conceptual & Futuristic & Technology. ]

The materials we use to create consumer products and infrastructure objects are constantly evolving as technology advances. The futuristic materials of a generation ago are commonplace today, just as the most amazing of new materials today will be completely familiar a generation from now. But right now, these 10 materials are some of the most fascinating and newsworthy substances in the world.

Gallium, the Metal that Melts in Your Hand

Although the above image looks like it’s been Photoshopped, it’s completely real. Gallium is a chemical element with such a low melting point that it turns to liquid in the human hand. It shatters like glass and breaks down other metals, but it’s non-toxic to humans.

Given its bizarre properties, gallium is understandably a favorite of scientists, science teachers and their students. The above videos show some of the most popular experiments using gallium, including one in which a spoon made of gallium melts in a cup of 85 degree (F) water.

Self-Healing Concrete for Smarter Streets

Repairing or replacing damaged concrete creates a financial and environmental burden. Smart materials which can repair themselves seem to be the future of construction technology, but most of those invented in recent years have required the addition of an outside material or stimulus to activate their healing properties. The smart concrete developed by University of Rhode Island engineering student Michelle Pelletier has microscopic capsules of a sodium silicate healing agent embedded in it. When a crack appears in the concrete, the sodium silicate acts with other components of the concrete to fix the cracks, sometimes making the structure even stronger than before.

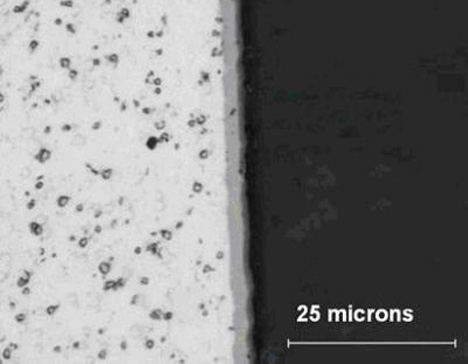

BAM!

Like many important materials, BAM was discovered accidentally. The combination of boron, aluminum, magnesium and titanium boride was discovered in 1999 by scientists at the US Department of Energy Laboratory in Ames, Iowa while they were looking for a material that generates electricity when heated. BAM is among the hardest materials in the world, surpassed only by diamond and cubic boron nitride. But perhaps even more impressively, BAM is also incredibly slippery, outperforming even Teflon. Coating industrial machine rotors with this wonder alloy could save U.S. industries upwards of $ 179 million a year in operating costs thanks to the resulting reduction in friction.

Temperature-Reactive Tiles

These color-changing glass tiles that are activated by temperature changes have the potential to turn every part of our world into a hypercolor dream. The tiles, made by a company called Moving Color, are already being used in showers but could also be used in kitchens, cars, appliances and cookware – just to name a few.

What a Robust Web They Weave…

It’s difficult to judge scale from the above photograph, but trust us: that is one massive spiderweb. It was made by a Darwin’s bark spider, found only on the island of Madagascar. These surprisingly small spiders (none over 2 centimeters or .78 inches have ever been observed) make some of the largest webs in the world. Even more impressive is the material of which the gigantic webs are made. The Darwin’s bark spider uses silk that is astonishingly strong: about 10 times stronger than Kevlar, in fact, making it the world’s toughest known biological material. The spider’s extraordinary natural silk is being studied so that we can someday create a human-made material that is nearly as tough.

To the Moon, ALICE!

This unassuming cylinder of grey stuff could change the way we go to the moon – and beyond. It’s a new type of rocket fuel made of aluminum and ice, ingredients which earned the fuel the name ALICE. The spacecraft fuel is being developed by researchers at Purdue University as a more environmentally friendly way to send Earthly machines into space. Current methods of propelling spacecraft put an enormous amount of pollutants into the atmosphere, but ALICE is kinder to our home planet. Researchers hope that the new fuel could even be made on the moon or Mars – or anywhere else water can be found – for a manned return flight, meaning that the outbound flight would not have to carry enough fuel for the return flight.

Starlite, Star Bright…

There is an amazing material that was invented way back in 1986 but still has not been widely used by any industry. Starlite is a plastic-like material that can withstand a nuclear blast or temperatures hotter than those on the surface of the sun. It was invented by a former hairstylist named Maurice Ward who was trying to develop an insulation material that would not emit toxic fumes in case of a fire. Instead, he came up with the miraculous Starlite – but he never commercialized his invention. Rumors about the fantastic material and its enigmatic inventor abound, but no one seems quite sure about why the material has never been put into widespread use. Sadly, we may never see Starlite reach its full potential; Ward died in 2011 and he was one of only two people on Earth who knew how Starlite is made.

Changing Phases

Scientists at the Technical University of Hamburg and the Institute for Metal Research in Shenyang, China use the example of cooking a breakfast egg to explain their research. The firmness of the egg can be adjusted just by changing the amount of time it is boiled. However, when an egg gets too firm, the cooking time can’t be reversed to make the egg softer again. Their research makes it possible for metals to change between hard and soft states with the touch of a button – a button that triggers an electric signal. This alone is an exciting development, but the scientific community is, as usual, looking ahead. They envision materials that can heal their cracks autonomously. They predict that in the future, “smart” metals and alloys will exist that can selectively become stronger when they sense an impact, thereby preventing damage.

Improving Your Lot in Life

Parking lots are disgusting, dirty places – largely because of the pollution inflicted by thousands of cars every day. The fluids that leak from cars onto the pavement are often washed right onto surrounding soil or nearby bodies of water. The Environmental Protection Agency wants to make parking lots a lot cleaner in the future, so they are studying an absorbent material that will soak up those vehicle fluids. Rather than being washed into the environment by rain or snow, the fluids flow through the permeable parking lot and into special collection tanks to be disposed of responsibly.

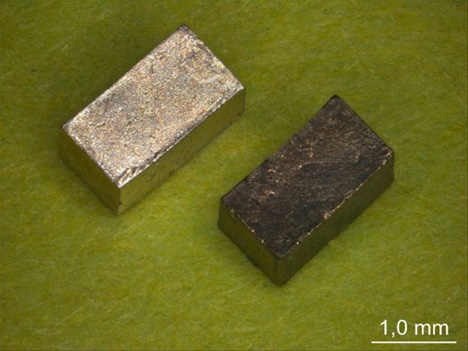

This Ship Has Sailed

International trading means that plenty of consumer products and materials are sent from one country to another on cargo ships. While this is an important part of global commerce, it is bad news for the environment since said cargo ships cause a huge amount of pollution. European Union researchers created a unique material meant to make super-light cargo ships possible. Aluminum foam, pictured above, is lighter than water and is very stiff. Sandwiched between two sheets of steel, the aluminum foam can withstand enormous force while allowing for an overall lighter ship and, therefore, lower fuel consumption. Tests indicate that the aluminum foam can cut down on ships’ weight by 30 percent, which could reduce CO2 emissions equivalent to 60 trucks’ worth for every super-light ship.

[ By Delana in Conceptual & Futuristic & Technology. ]

[ WebUrbanist | Archives | Galleries | Privacy | TOS ]

![]()

You must be logged in to post a comment.