|

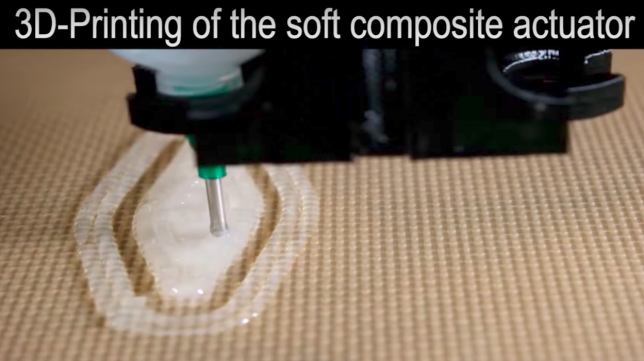

One of the accessories you can purchase for some of Lomography’s instant cameras is the Splitzer, an add-on component that makes it possible to shoot multiple exposures on the same frame. Unfortunately, the accessory isn’t available for the Fujifilm Instax Mini 90, but photographer Guillermo Hernandez has managed to create his own 3D-printed version for the popular camera.

Like the Splitzer, the 3D-printed component simply attaches to the front of the lens. To capture a double exposure, simply cover the half of the frame you don’t want exposed, take a shot, then rotate the Splitzer 180-degrees before taking another shot.

|

As you can see in the sample photos below, this allows you to create unique compositions wherein a single subjects can be in two places at once or frame the same object side-by-side.

$ (document).ready(function() { SampleGalleryV2({“containerId”:”embeddedSampleGallery_9993708725″,”galleryId”:”9993708725″,”isEmbeddedWidget”:true,”selectedImageIndex”:0,”isMobile”:false}) });

It’s undoubtedly a novel accessory, but it’s a fun way to get a little more out of a Fujifilm Instax camera. Hernandez is selling his Instax Mini 90 Splitzer in multiple colors for $ 5 on eBay with $ 3 shipping, but if you have access to a 3D printer and know some basic CAD tutorials you could probably whip up one yourself. Hernandez has other 3D-printed photo-related products on his eBay store, too.

Articles: Digital Photography Review (dpreview.com)

You must be logged in to post a comment.