Sony Kumamoto sensor factory: first public footage of the 2016 earthquake

|

On April 16, 2016, disaster struck in Kumamoto in the Kyushu region of Japan. A series of earthquakes, including an unprecedented 7.0 mainshock struck beneath Kumamoto City where Sony’s sensor factory resides. The factory itself was a mere 20 kilometers from the earthquake’s epicenter. A foreshock (warning) of magnitude 6.2 came approximately two days earlier, which gave the factory time to evacuate; however, the damage to the carefully built, precision controlled and automated factory with clean rooms was devastating. Not to mention the impact on the lives of those in the region…

During a recent trip to the repaired Kumamoto factory, DPReview was afforded an inside look at the facility and a chance to meet the very people that keep one of the world’s largest sources of imaging sensors operational. We watched a video that showed the extent of the damages and repair efforts. Combined with a better of understanding of how the facility operates, we were able to appreciate just how extensive the destruction and repair processes were. We’ll get to that in the following slides, but have a look above at the public’s first look of footage from the facility during the earthquake, and the massive repair efforts that followed.

Massive impact

|

Before we dive more into the impact on Sony’s sensor factory itself, we’d be remiss to not mention the impact on the region. The foreshock and mainshock together claimed more than 50 lives, injured 3,000 others, forced more than 44,000 people to evacuate from their homes and left over 180,000 people seeking shelter in the days after the earthquake. The entire city of Kumamoto was left without water, flights were grounded, as was rail service due to a derailed train. A thousand buildings had been seriously damaged either directly by the earthquake or due to the resulting fires and landslides, and an entire hospital had to be evacuated due to the building being knocked off its foundation.

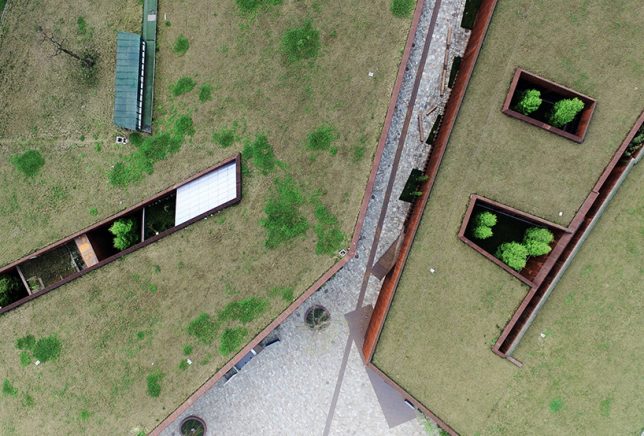

More than 140 aftershocks were registered within just two days. The estimated economic costs due to the earthquake are estimated to be up to $ 7.5 billion USD. Although you can’t quite appreciate it in this image, the sensor factory is surrounded by mountainous hills resulting from a tectonic line housing many active faults. Earthquakes of some magnitude or another are common to the area. In the following days we’ll have more pictures of the area, as we traveled extensively within the Kyushu region.

Source of statistics: Wikipedia

‘The outside was visible from inside the clean-room’

|

Many sections of the 40,000 square meter facility were severely damaged. There were continued aftershocks for many days that made it difficult to even re-enter and start repairs. In fact, the region is used to After it was deemed safe to enter, the damage was assessed. It was extensive. Heavy duty H-beams for structural support buckled, causing walls and ceilings to collapse. Here is an image showing the ceiling of the clean room ripped open, exposing the sky above. ‘Now we were speechless’ said the camera crew filming the damage.

And those ceilings aren’t your typical roofs over your head: they house tracks that carry many of the parts from machine to machine in the automated processes of taking a silicon wafer and generating active sensors from them. Essentially, many parts of the sensor development process were disrupted.

Delicate, precision machinery: shattered

The extensive damage to the clean room meant that many of the machines automatically processing silicon wafers to generate sensors* were destroyed, including the many wafers each machine contained. Throughout the video you’ll see shattered silicon – at various stages of the silicon-to-sensor process – scattered everywhere. Ultimately many functional machines were salvaged, removed, and brought back after the clean room was reconstructed, but many were deemed too damaged to ever function again.

* Stay tuned for an in-depth look at the actual sensor manufacturing process, which we learned about during a recent trip to the factory.

All hands on deck

|

The sensor factory in Kumamoto produces most sensors Sony manufactures not just for their own cameras, but for other manufacturers as well, including those in the smartphone, security camera, webcam, automotive, medical and other imaging-related industries. The disruption of this facility had no small impact: consider that by July 2017, Sony has sold 7.2 billion sensors worldwide.

Therefore, it was imperative to restore operations to normal as soon as possible. And that’s why Sony factory members themselves, including executive ones, went to work right away restoring the factory. There are nearly 2700 employees at this factor, and it was all hands on deck.

A spirit of personal responsibility and dedication

Imagine an earthquake at your corporate office that ruined much of your workspace. Would you expect to return to clean up and help repair the damage yourself? That’s what the Kumamoto employees did. The spirit is really remarkable when you stop to consider that most of us here in the States would expect our companies to simply ‘deal with it’. Here is a factory employee vacuuming up thousands of fragments of broken silicon wafers.

Operations resumed ahead of schedule

|

The factories worked with such diligence and dedication that they restored operations ahead of schedule. They did this whilst putting in place precautions that would lower the lead time from 3.5 months to 2 months were this sort of disaster to happen in the future. These measures included stronger piping as well as the engineering of self-stop systems that halt precision processes when shake is detected. These systems respond in particular to P-waves, the first of two major elastic seismic waves to arrive at a seismograph during an earthquake.

A human story of courage, dedication and ultimate success

|

And so the story ends on a happy note. Here is an image of the team of employees that worked countless hours to restore the Kumamoto facility to normal operations. We can only imagine the dedication involved, and how heartening it was to work together to bring back to life such an important part of the company. It’s a story of not just company dedication and culture, but a human one of working together to achieve an honorable goal.

We were obviously touched watching the video and seeing the spirit of the employees. Were you? Let us know in the comments below.

Articles: Digital Photography Review (dpreview.com)

You must be logged in to post a comment.